Powder Coating

MOS Finishing offers a huge selection of long-lasting protective powder coating options in Orange County, CA and surrounding areas.

Get a Quote

What Is Powder Coating?

To understand the process of powder coating,

you first need to know what it is...

Powder coating is a finishing method used on metal surfaces. The powder itself is a polymer resin combined with pigment, curing agents and other additives that is sprayed onto an electrically-charged metal surface. The charge is what enables the powder to adhere to the surface, and it is baked on once the spraying is completed.

A properly applied and cured powder coat finish should last indefinitely, even with heavy use. In the event that the coating somehow gets scratched, it is possible to strip and re-coat the piece, though this isn’t a top concern with powder coating.

The Process of Powder Coating

While many powder coating shops use tumblers or conveyors to coat multiple pieces at once, MOS hand-coats every piece to ensure maximum coverage and an even layer of powder.

Prior to applying the powder, the surface of the metal must be cleaned and pretreated using a phosphate solution or other suitable cleaning agent. This preparation will remove oils and dirt to allow the finish to properly adhere to the metal surface, enlongating its life and ensuring its durability. A properly-prepped surface can also prevent damage or imperfections such as blistering, bubbling, alligatoring, or cissing.

During the application stage, the powder granules and the metal surface are charged with electrostatic energy to ensure complete adhesion of the finish. The powder is sprayed onto the surface with an electrostatic gun, and the electric charges cause the powder particles to seek out and adhere to the metal surface of the item being coated. Once the powder settles onto the surface, it melts and fuses into a smooth coating before going into the curing oven.

Once the powder coating has been applied and allowed to melt, the finish is cured in a dry heat oven at temperatures of 400°F or more. Curing allows the melted powder to settle onto the surface, where it will harden to form a long-lasting protective shell over the metal. MOS’ curing ovens can accommodate items up to 20 feet long and 8 feet tall.

As a time-tested method of finishing, powder coating continues to be considered the superior finish across industries.

While it’s not necessarily the right choice for every project, such as small parts with tight tolerance requirements, it provides the vast majority of projects with a durable finish that won’t chip, fade or crack, is environmentally-friendly and can be achieved in any color, hue and texture.

The Benefits of Powder Coating

Powder coating provides strength, durability and aesthetics to nearly any metal piece. Here are some of the top benefits that come with this choice of coating over liquid paint:

Cost Efficiency – Powder is a less expensive option than liquid paint, and the powder bases can be safely stored for future use rather than being wasted. Since there’s little to no waste associated with the application process, waste and cleanup costs are minimized.

Consistency – Liquid paint can drip and spread unevenly, while powder coating provides smooth, consistent surfaces with no toxic fumes.

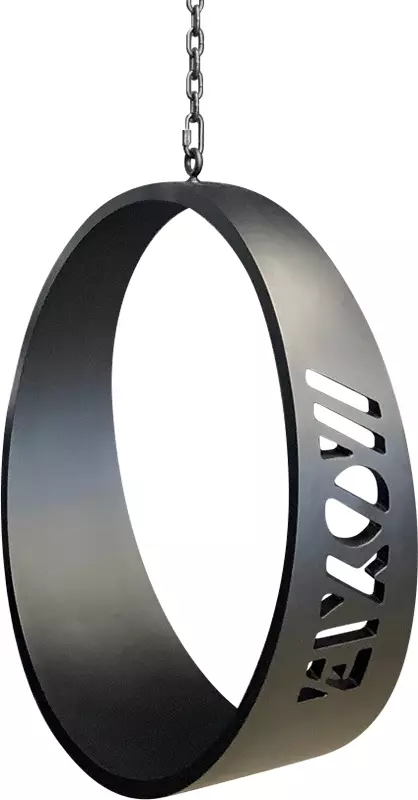

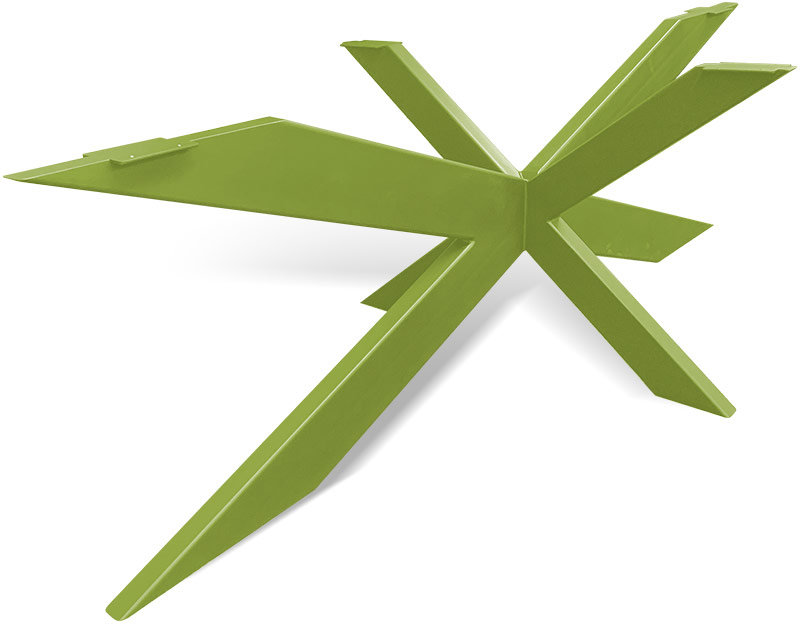

Coverage – Whereas it is sometimes difficult using paint, powder coating can evenly coat intricate surfaces, leaving a uniform finish across the entire piece.

Customization – We can custom-mix our powder coatings to match any desired color, and there are many different finishes available (gloss, texture, metallic, etc.). What’s more is that the coating is resistant to wear and tear such as fading, chipping and scratching.

Eco-friendliness – The powder does not contain harsh chemicals or VOCs, and the electrical charge ensures no solvents are needed for the powder to adhere to the metal.

Expediency – The application process is fast and requires fewer labor hours than traditional painting methods. With powder coating, most projects require only a single coat, helping to minimize project costs and completion time.

Longevity – Powder coatings are not only durable and weather-resistant, but they also require minimal maintenance and are easy to clean. These features contribute heavily to powder coating’s superior protection against corrosion and wear.

Powder Coating FAQs

While powder coating is easy to care for and maintain, no coating is completely exempt from needing to be cleaned occasionally. When it comes to powder coating, you should avoid harsh chemical cleaners, as they may cause accelerated degradation of the finish. One of the most common and efficient ways to clean a powder-coated surface is by pressure washing it at a low setting using filtered water (this is important; unfiltered water can stain the metal). For smaller or more delicate surfaces, a soft cloth paired with mild soap and water can safely be used to wipe away dirt and dust. Still have questions? Contact us

While powder coating is durable enough to withstand even the heaviest industrial usage, it’s not invincible. Accidents happen and sometimes coatings can be damaged. Luckily, it’s not only possible to repair a damaged powder coating, it’s actually quite a simple process. That said, it is a process that should be done by professionals; if you have damaged powder coating, call MOS Finishing to schedule a time to bring in your product for repair.

Unlike paint, powder coating does not need to sit and dry for an extended period of time. In fact, powder coating doesn’t need to be dried at all; rather, it’s cured in a special oven at around 400°F for a length of time determined by the size and composition of the piece being coated. Overall, the whole process is much faster than painting. While MOS powder coats a wide range of parts, pieces and products, to provide some perspective, a set of 4 rims can typically be powder coated within a day (at approximately 2 hours per rim).

If you love the way your powder coated products look, you might be concerned about anything that could compromise the aesthetics. Powder coating is exceptionally durable, but there are some simple steps you can take to ensure an extended lifespan.

Avoid harsh chemicals – Certain cleaning solvents (such as acetone) can damage powder coating and even the metal underneath.

Cleaning DOs – Clean dust off of powder coatings with a soft cloth; if it needs to be cleaned more thoroughly, use a mild soap mixed with filtered water to gently wipe away dirt. Rinse with clean water and dry with a soft cloth.

Apply wax – To further preserve both the aesthetics and functionality of your powder coating, apply a thin layer of automobile wax after cleaning. Let the wax dry, then gently wipe it off with a soft, dry towel.

Don’t try to fix damaged powder coat – If your powder coating has become scratched, chipped or cracked, it’s NOT ok to use paint to touch it up. Paint will not properly adhere to powder coating. Take your damaged powder coated product to a professional for repair. MOS can repair most damaged powder coatings without needing to strip and re-coat the part, making the process even faster and less expensive.

Maintain your surfaces – Like most things you want to preserve, you should inspect and clean your powder coated surfaces at least once a year, more often if you live in a coastal area or have had extreme weather (if your products are exposed to these elements). You shouldn’t clean these surfaces too often, but you should give it a gentle wipe occasionally to get rid of the dust.

MOS Finishing is Orange County’s Preferred Powder Coating Team

The team at MOS is highly-trained and focused on delivering not only impeccable products but superior customer service, as well. We’re happy to evaluate and help you identify your best coating options that meet your protection and aesthetic needs.

Request a Quote